What Is a CNC Machine? A Beginner’s Guide to CNC and Advanced Manufacturing

If you’ve ever been curious about how modern products, from airplane parts to medical devices, are made with such incredible precision, there’s a good chance a CNC machine was involved. Whether you’re considering a career in machining or just starting to explore the world of advanced manufacturing, understanding what a CNC machine is (and why it’s important) is the first step. So, what is a CNC Machine?

What Does CNC Mean?

CNC stands for Computer Numerical Control. A CNC machine is a type of automated equipment that follows precise instructions from a computer program to cut, drill, mill, turn, or shape raw materials like metal, plastic, or composites into finished parts.

Think of it like this: A CNC machine is the high-tech cousin of a traditional lathe or mill—but instead of being operated by hand, it’s driven by software and code.

What Are The Steps In Using A CNC Machine?

- Design – A part starts as a digital drawing, often made in CAD (Computer-Aided Design) software.

- Programming – That design is converted into G-code—a language the CNC machine understands. You may also hear about proprietary languages like Mazatrol, which is used on Mazak machines.

- Setup – A machinist or operator installs the right tools and materials on the machine.

- Execution – The machine follows the code to produce the part with exact precision, often down to thousandths of an inch.

Types of CNC Machines

There are several types of CNC machines, each suited to different kinds of work. Below are the most common types you’ll encounter in the field.

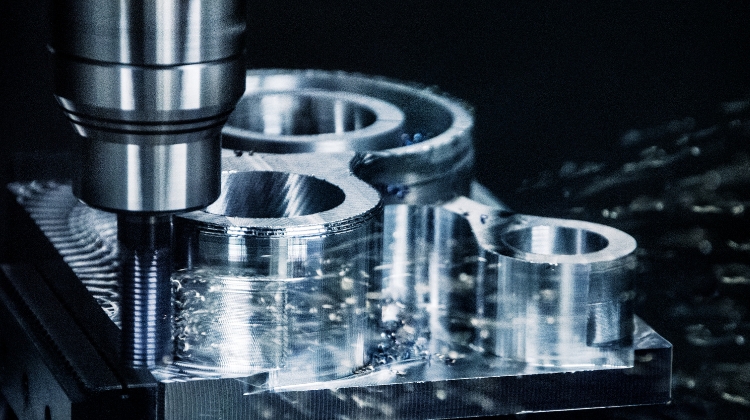

CNC Mills

CNC mills use rotating tools to remove material from a solid block (also called a workpiece). They are commonly used to create complex parts with flat or contoured surfaces.

Common uses: metal brackets, housings, prototypes

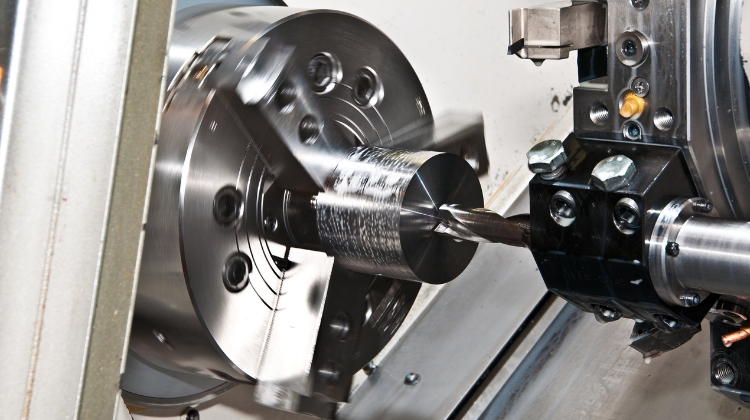

CNC Lathes

CNC lathes rotate the material while a stationary tool shapes it. These machines are ideal for producing round or cylindrical parts.

Common uses: shafts, bushings, threaded parts

CNC Routers

CNC routers are similar to mills but are typically used for softer materials like wood, plastic, or foam. They’re popular in furniture making, signage, and prototyping.

Common uses: custom panels, signage, wood carvings

CNC EDM (Electrical Discharge Machines)

EDM machines cut through hard materials using electrical sparks. They’re used when extremely precise cuts are needed, especially in tool and die making.

Common uses: injection mold components, fine-detail parts

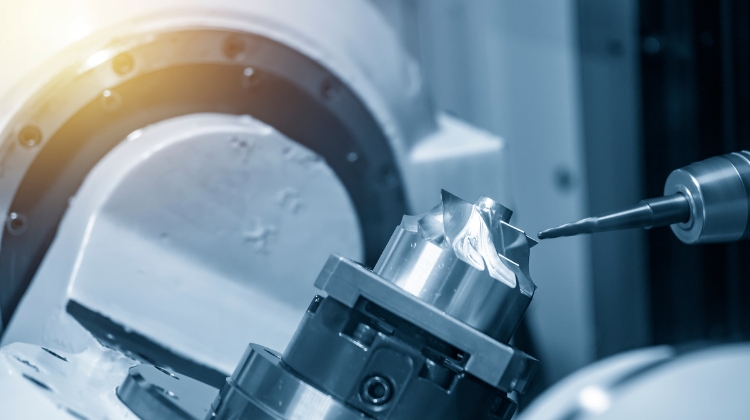

Multi-Axis CNC Machines

These machines can move in 4, 5, or even more axes, allowing them to machine complex parts in fewer setups. They’re used heavily in aerospace, medical, and advanced manufacturing.

Common uses: turbine blades, prosthetics, aerospace brackets

Why CNC Machines Matter in Manufacturing

CNC technology plays a critical role in nearly every modern industry. Here’s why:

- Precision – CNC machines produce parts with extremely tight tolerances.

- Efficiency – Automated workflows reduce production time and material waste.

- Consistency – Every part can be made exactly the same, down to the last detail.

- Flexibility – CNC machines can switch from one job to another with minimal downtime.

From cars and airplanes to smartphones and surgical tools, CNC manufacturing makes the modern world possible.

Careers in CNC and Advanced Manufacturing

If you like working with your hands and solving problems with technology, CNC could be a great fit. Here are a few common roles:

- CNC Operator – Loads materials, runs machines, and monitors production.

- CNC Machinist – Sets up machines, tweaks programs, and ensures quality.

- CNC Programmer – Creates the code that machines follow.

- Quality Inspector – Verifies that finished parts meet strict standards.

- Manufacturing Engineer – Designs workflows and improves shop-floor efficiency.

Most roles require hands-on training, which you can gain through trade school, apprenticeships, or on-the-job experience.

Getting Started

If you’re interested in CNC but aren’t sure where to begin, you’re not alone—and you’re in the right place. There are several ways to start building a career in CNC and advanced manufacturing, even with little or no prior experience.

Here are two great starting points:

- How to Get Started in CNC – A beginner-friendly guide that walks you through what to expect, what skills matter most, and how to find your first opportunity in the field.

- Trade School Directory – Explore hands-on training programs near you that can prepare you for entry-level roles in machining, programming, and manufacturing technology.

Some employers will even pay to train you. Whether you’re switching careers or just out of high school, the path to a rewarding job in CNC is more accessible than you might think.

Final Thoughts

Behind every precision-cut engine part, surgical instrument, or aerospace component is someone who knows how to run a CNC machine—and that someone could be you. If you enjoy solving problems, working with cutting-edge technology, and creating things you can see and touch, CNC might be the perfect career.

The industry is growing fast, and it needs smart, motivated people to grow with it. Whether you’re aiming to be a machinist, a programmer, or a manufacturing engineer, your journey can start today.

Explore CNC machining jobs, entry-level opportunities, and skilled trade careers on OnlyCNCJobs.com – the premier job board built specifically for CNC machinists, programmers, and advanced manufacturing professionals.

About the Author

Will Brent is the Co-founder and Managing Director of Career Copia, the parent company of Only CNC Jobs. With a background in technology and deep experience in skilled trade recruiting, Will focuses on developing smart, human-centered solutions to hiring challenges in the advanced manufacturing space.

Outside of work, Will is a lifelong motorsports fan and avid tinkerer. He spends his spare time working on his own car and designing parts in Fusion 360—often bringing ideas to life through 3D printing or CNC machining. Whether it’s solving a problem around the house or optimizing a project in the garage, Will’s passion for engineering and precision craftsmanship drives both his professional and personal life.